Our Client is a leading chemical processing manufacturer with a distinct expertise in the conversion of hydrochloride powder into liquid solutions, tailored specifically for the poultry and water farm industries. Committed to delivering innovative and high-quality solutions, our client operates from its base in Virginia, USA, while also extending its reach to international markets, notably including export activities to countries like China.

The focus of this case study lies in the operational challenges faced by Superb Solutions in the realms of inventory management and distribution. The transformative journey of the company was ignited by the integration of the Odoo ERP system, skillfully implemented by Banibro, ushering in a new era of operational efficiency and success.

Significant operational difficulties were faced by our customer, a well-known chemical production company, which affected their scalability and efficiency:

1. Problems with Inventory Management: Had trouble keeping track of and maintaining stock levels for both completed goods and raw supplies.

2. Intricate Logistics of Distribution : Oversaw the various demands of distribution, particularly when handling various product forms and guaranteeing prompt delivery.

3. Ineffective Billing and Sales Procedures: Required an efficient system to manage sales, which included drafting and maintaining bills of lading and other shipping paperwork.

4. Communication Gaps: Poor departmental communication caused delays, misunderstandings, and problems with coordination, which reduced total productivity.

5. Problems with maintenance and safety: Manual procedures made it difficult to schedule maintenance and comply with safety regulations, which led to more downtime and jeopardized safety.

6. Financial Reporting Issues : The use of inconsistent systems and manual data entry resulted in inaccurate reporting, a delay in reporting, and difficulties obtaining a thorough financial picture.

1. First Evaluation and Tailoring :

Performed a thorough analysis of the unique requirements of the customer, adjusting the inventory management and sales modules of Odoo ERP accordingly.

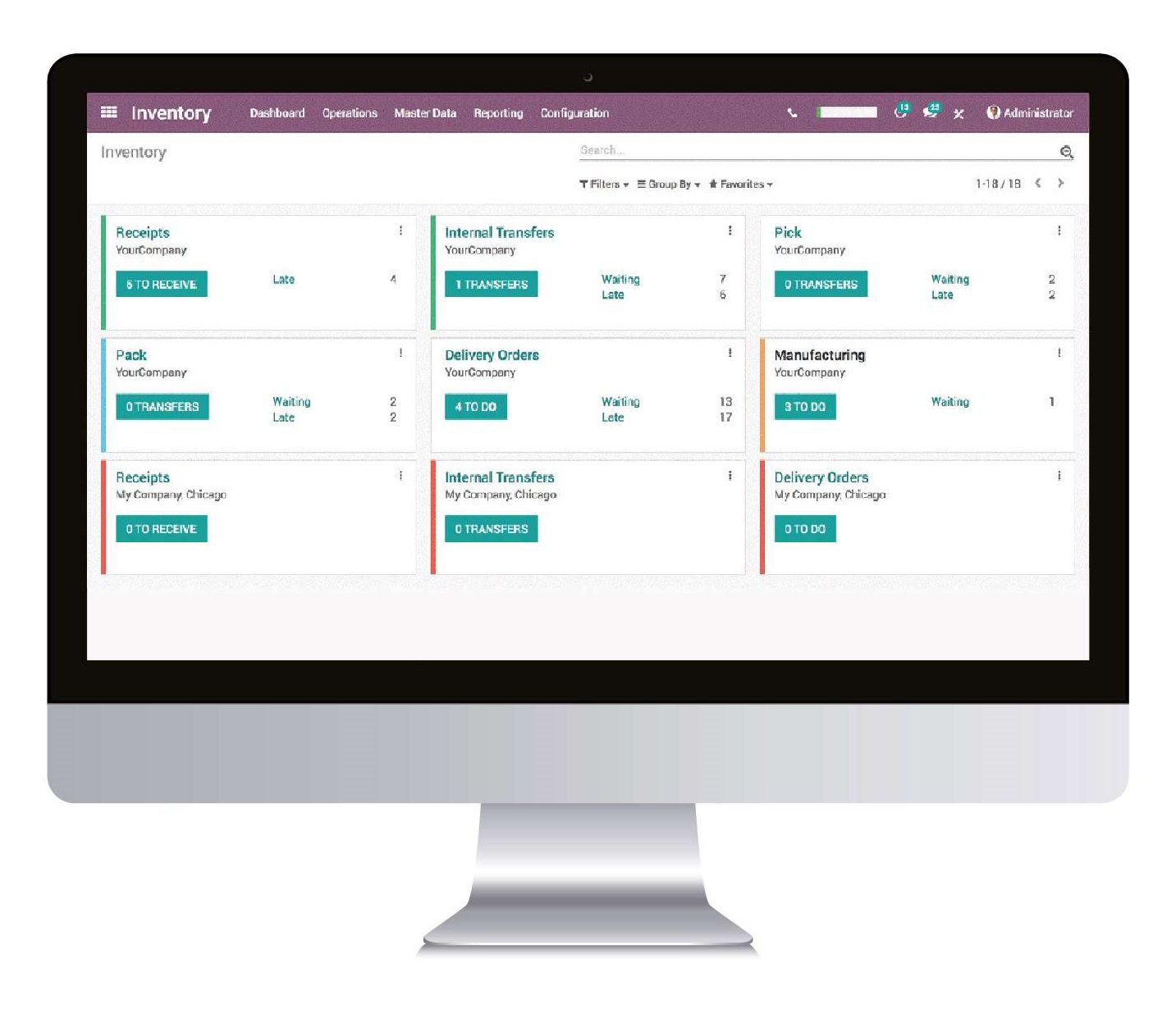

2. Redesigning the Inventory Management System : Odoo ERP was customized for automated updates and real-time tracking, guaranteeing precise forecasting and lowering the possibility of stockouts or overstocking.

3. Simplifying Logistics and Distribution :

Modified the distribution modules of Odoo ERP to manage intricate logistics, enhancing delivery timetables and shipment tracking.

4. Improvement of the Sales and Billing Process: Outfitted ERP with tools to streamline sales, such as bills of lading templates that can be customized to increase efficiency and accuracy.

5. Education and Assimilation: Offered thorough training to the client’s employees to guarantee a seamless transfer and complete integration of Odoo ERP into regular operations.

Odoo ERP installation led to notable advancements in:

1. Better Inventory Management: Better stock level monitoring and management, which boosts operational effectiveness.

2. Greater Distribution Effectiveness: More efficient and effective distribution procedures that guarantee on-time delivery by improving customer satisfaction and cutting delivery delays by almost 98%.

3. Enhanced Operations for Sales and Billing: A roughly 25% boost in revenue was achieved through quicker and more precise sales processing, which also reduced errors and administrative overhead.

The chemical manufacturing company’s operations have been greatly improved by the integration of Odoo modules, which offer a smooth workflow from sourcing to manufacturing and distribution. Odoo’s adaptability and customization features meet the unique requirements of the business, boosting productivity and fostering general success.