- Home

- Company

- Our Services

Odoo Services

ERP Services

- Odoo Apps

- Our Industries

- Locations

- Resources

- Contact us

Call us today!

+91 93422 58771

- Home

- Company

- Our Services

Odoo Services

ERP Services

- Odoo Apps

- Our Industries

- Locations

- Resources

- Contact us

Call us today!

+91 93422 58771

For a high-quality spice powders and masala manufacturer, our client has established a strong presence in the market. With a wide range of products and a growing customer base, they faced significant challenges in managing their operations efficiently. To enhance productivity, improve resource utilization, and streamline their processes, they decided to implement a robust Odoo for manufacturing company.

Prior to implementing the Odoo ERP software, the client encountered several challenges stemming from inefficient processes and lack of integration, including:

1.Poor Communication between Departments: The client struggled with communication gaps between different departments, resulting in delays, miscommunications, and coordination issues. This hindered the overall efficiency of their operations and impacted customer satisfaction.

2. Improper Maintenance and Safety Processes: Due to manual processes, the client faced challenges in maintaining proper maintenance schedules and ensuring compliance with safety regulations. This led to increased downtime, compromised product quality, and safety concerns.

3. Entire Financial Reporting: The client relied on manual data entry and disparate systems for financial reporting, leading to inaccuracies, delayed reporting, and difficulties in gaining a comprehensive financial overview of their operations.

To address these challenges, our team adopted a comprehensive approach to implement a tailored Odoo ERP manufacturing solution. The key steps we took included:

1. Requirements Analysis: We conducted an in-depth analysis of the client’s existing processes, including communication workflows, maintenance practices, and financial reporting requirements. This helped us identify specific pain points and define a roadmap for the ERP implementation.

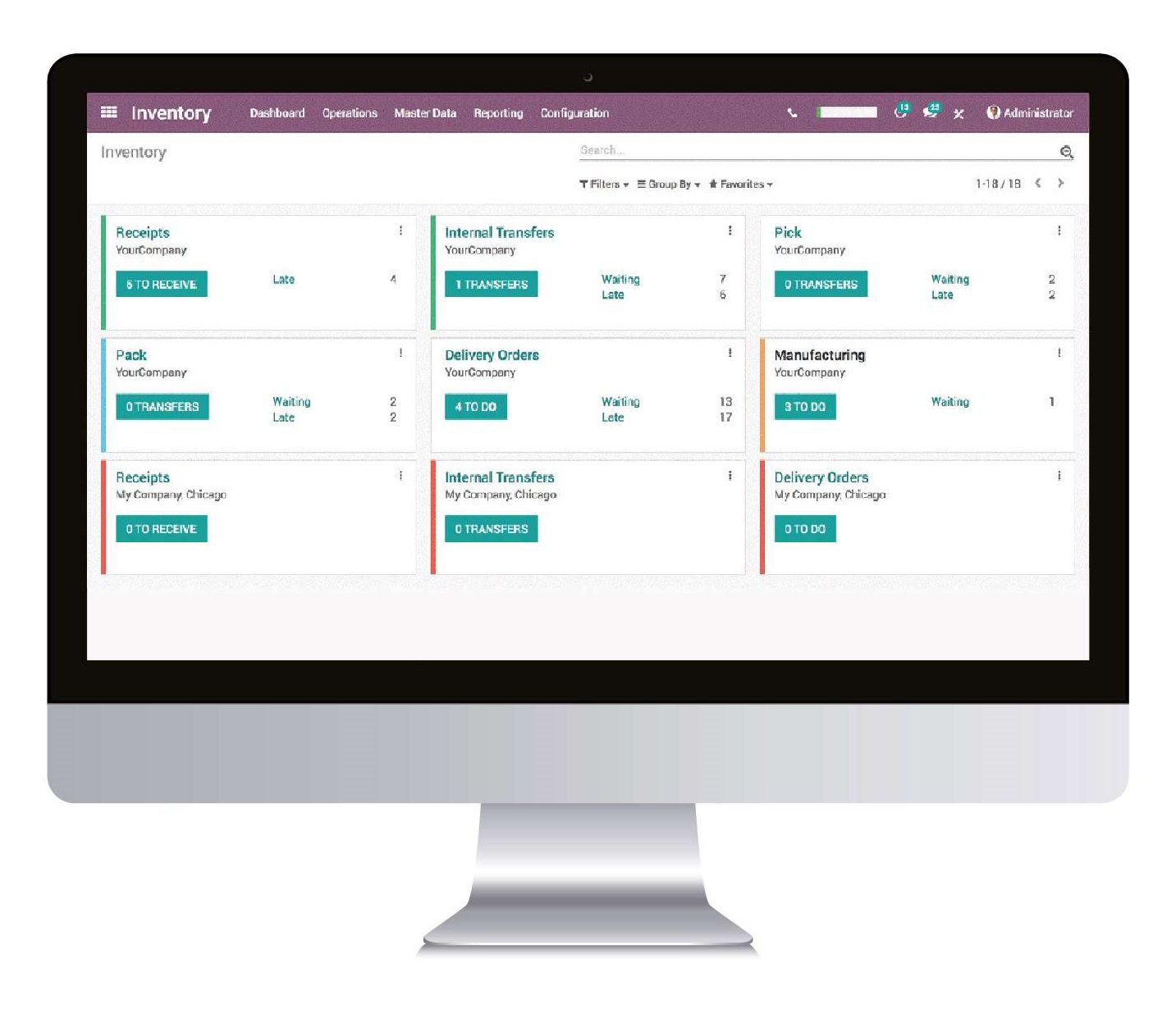

2. System Selection: Based on the client’s requirements, we proposed the Odoo Manufacturing ERP. We considered factors such as functionality, ease of use, integration capabilities, and support for communication, maintenance, and financial modules to select the most suitable solution.

Customization and Integration: We collaborated closely with the client to customize the ERP software, ensuring it aligned with their unique manufacturing processes. Additionally, we have installed Maintenance, Quality and Accounting modules to ensure seamless data flow and process automation.

4. Data Migration and Training: We facilitated a smooth transition by migrating the client’s data from their legacy systems to the new ERP software, ensuring data integrity and accuracy. We also provided comprehensive training to their employees, enabling them to effectively utilize the new system.

The implementation of the Odoo Manufacturing ERP software brought about significant improvements in the client’s operations. Key highlights of our solution included:

1. Improved Communication and Collaboration: The ERP software enabled seamless communication and collaboration between different departments, fostering a more efficient and coordinated workflow. This led to faster response times, reduced errors, and improved customer satisfaction.

2. Streamlined Maintenance and Safety Processes: The ERP system facilitated automated maintenance scheduling, tracking, and compliance management. This resulted in improved equipment uptime, enhanced product quality, and a safer working environment.

3. Accurate Financial Reporting: With the ERP software, the client achieved accurate financial reporting, eliminating manual data entry and consolidating financial data from various departments. This led to accurate and timely financial reporting, improved decision-making, and enhanced financial transparency.

The implementation of the Odoo Manufacturing ERP yielded significant results for our client, including:

1. 25% Increase in Operational Efficiency: The streamlined processes and improved communication facilitated by the ERP software led to a 25% increase in overall operational efficiency.

2. 20% Reduction in Maintenance Costs: By automating maintenance processes and optimizing schedules, the client achieved a 20% reduction in maintenance costs, minimizing downtime and enhancing equipment reliability.

3. Improvement in Financial Reporting Accuracy: 30% The integrated financial modules of the ERP system resulted in a 30% improvement in the accuracy and timeliness .

Want to know how we can help?

Get Free Consultation

+91-93422 58771

SAY HELLO!

info@banibro.com

For Enquiry